Conveyors & Monorails

Foundry Projects Limited provide various custom built conveyors and monorails for numerous material handling applications. Each system is completely bespoke to suit the client’s exact requirements but the main element they all have in common is that they need to be extremely robust which the nature of foundry industry demands.

Types of conveyor we have provided include:

- Rubber Belt Conveyors

- Side Wall Belt Conveyors

- Trough Belt Conveyors

- Metal Slat Conveyors

- Vertical Bucket Elevators

Monorail systems we have provided are typically used for:

- Casting / pouring

- Hot metal transfer

- General part transfer

- Charging of coke, limestone and additions

- Loading of hoppers

Conveyor Products

Rubber belt conveying systemShow Full Screen

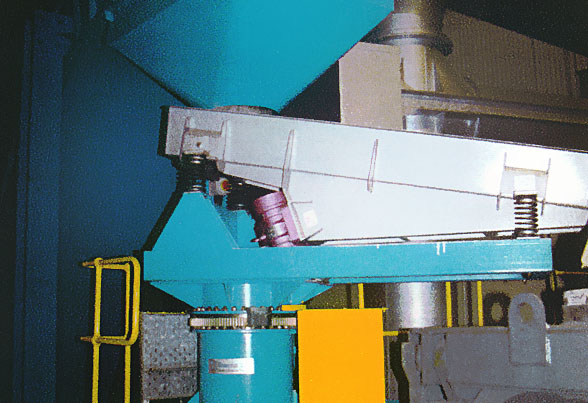

Rubber belt conveying systemShow Full Screen Conveyor discharging onto a slewing vibratory feederShow Full Screen

Conveyor discharging onto a slewing vibratory feederShow Full Screen Shultz belt conveyorShow Full Screen

Shultz belt conveyorShow Full Screen Sand storage hopper incorporating conveyor underShow Full Screen

Sand storage hopper incorporating conveyor underShow Full Screen Conveyor loadingShow Full Screen

Conveyor loadingShow Full Screen Foundry sand trough conveyorShow Full Screen

Foundry sand trough conveyorShow Full Screen

We can offer the conveyor as a standalone item or part of a complete handling solution to include items such as vibratory feeders and storage hoppers.

We design each conveyor with only the best available procured parts such as high quality rubber belt, bearings, rollers and motors and we offer options such as head scraper systems, belt tracking systems, grab wire safety switches and guarding.

Monorail Products

Indexing monorail for dye lineShow Full Screen

Indexing monorail for dye lineShow Full Screen Powered electric hoist and bus bar systemShow Full Screen

Powered electric hoist and bus bar systemShow Full Screen Free standing monorailShow Full Screen

Free standing monorailShow Full Screen Monorail servicing ndt systemShow Full Screen

Monorail servicing ndt systemShow Full Screen Hot metal transfer casting monorailShow Full Screen

Hot metal transfer casting monorailShow Full Screen Hot metal transfer casting monorailShow Full Screen

Hot metal transfer casting monorailShow Full Screen Monorail rolling junctionShow Full Screen

Monorail rolling junctionShow Full Screen

We can offer manual hoists or electric chain hoists as required.

We use standard Bus Bars to provide the power to the electric chain hoists and we can provide weighing stations and raise/lower stations if required.

Each system would be load tested on completion.

Foundry Equipment & Products