Dye Penetrant Testing (NDT)

Foundry Projects Limited have supplied several NDT Systems all based on using dye penetration for the purpose of crack detection. Each system is a unique design and there are many options in terms of layout and position of each process station. The complete system would comprise of many individual processes which would be tailored to suit the clients process requirements, part sizes, space available to site the plant and of course part loading and discharge into and away from the system.

Dye Penetrant Testing Systems

NDT complete systemShow Full Screen

NDT complete systemShow Full Screen Dye penetrant electro-static spraying pump setsShow Full Screen

Dye penetrant electro-static spraying pump setsShow Full Screen NDT system under constructionShow Full Screen

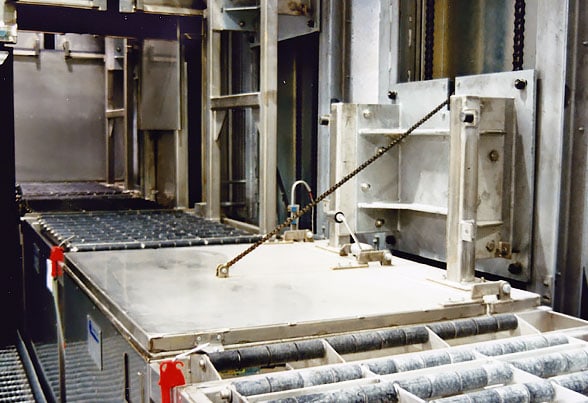

NDT system under constructionShow Full Screen NDT system gravity roller trackShow Full Screen

NDT system gravity roller trackShow Full Screen Independent tanks with integral raise/lower and lid mechanism’sShow Full Screen

Independent tanks with integral raise/lower and lid mechanism’sShow Full Screen

Where required we have integrated slat conveyors into the process which can be set at a variable slow speed to provide a required dye contact time for the duration period while the part travels the full length of the conveyor.

All platforms, monorail structures, guarding and services are provided apart from any civil and drainage requirements so we can offer nearly a turnkey solution.

Should you have any requirements or questions regarding Dye Penetrant Testing then please do not hesitate in contacting us for more information.

Foundry Equipment & Products