X

Museum demonstration 1t/hour cupolaShow Full Screen

Museum demonstration 1t/hour cupolaShow Full Screen Pair of 8t/hr cupolas during constructionShow Full Screen

Pair of 8t/hr cupolas during constructionShow Full Screen Pair of 8t/hr cupolas during constructionShow Full Screen

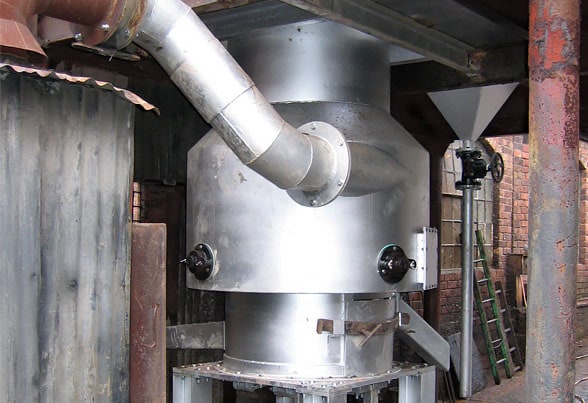

Pair of 8t/hr cupolas during constructionShow Full Screen Cupola fume extraction plant during constructionShow Full Screen

Cupola fume extraction plant during constructionShow Full Screen Pair of cupola wet-arrestersShow Full Screen

Pair of cupola wet-arrestersShow Full Screen Pair of arrester chimney extensionsShow Full Screen

Pair of arrester chimney extensionsShow Full Screen Pair of arrester chimney extensionsShow Full Screen

Pair of arrester chimney extensionsShow Full Screen Replacement wet-arrestersShow Full Screen

Replacement wet-arrestersShow Full Screen Installation of a recuperatorShow Full Screen

Installation of a recuperatorShow Full Screen

The three main reasons why are, the initial capital installation cost is relatively low, the cupola is easy to operate and thus semi skilled labour can be used during the melting operation and the cupola is extremely flexible and is capable of melting many forms of scrap metals from high grades to the very lowest grades and at the same time producing high quality irons.

Foundry Equipment & Products