X

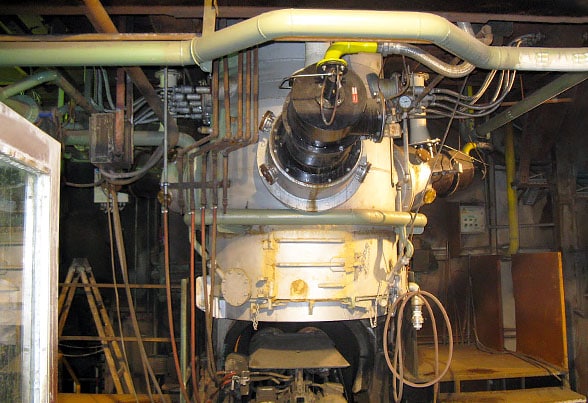

8t/hour cupolaShow Full Screen

8t/hour cupolaShow Full Screen 10t/hour cupolaShow Full Screen

10t/hour cupolaShow Full Screen 20t/hour cupolaShow Full Screen

20t/hour cupolaShow Full Screen DuplexingShow Full Screen

DuplexingShow Full Screen 5t/hour cupolaShow Full Screen

5t/hour cupolaShow Full Screen 6t/hour cupolaShow Full Screen

6t/hour cupolaShow Full Screen Cupola and duplexing systemShow Full Screen

Cupola and duplexing systemShow Full Screen Stone wool cupolaShow Full Screen

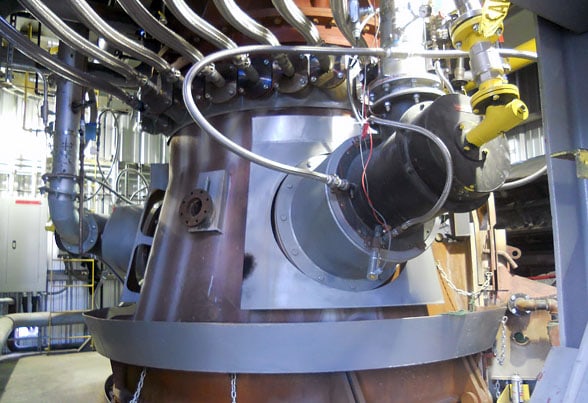

Stone wool cupolaShow Full Screen Grate bar and combustion systemShow Full Screen

Grate bar and combustion systemShow Full Screen

It requires around half of the base energy to melt a given tonne of iron and can operate without any visible emission even when using dirty materials.

There are significant reductions in the amount of emissions of sulphur and nitric oxides and no sulphur absorption makes the furnace ideal for the production of ductile or nodular iron.

Foundry Equipment & Products